10 Year CFZ

Ten years ago, we made a hoodie so good, you called it “great.” Made from all-American materials like hardwearing ringspun cotton, with functional details designed to last. Sewn and washed in Middlesex, North Carolina (population: 1,037), where we’ve been making it since 2013. Now, we’re celebrating our hoodie’s tenth birthday by sharing its story, and honoring the people behind the product.

THE GOAL WAS NEVER TO MAKE "THE GREATEST HOODIE EVER MADE." FROM THE BEGINNING, THE GOAL WAS TO SUPPORT OUR PEOPLE.

When I started American Giant,I saw boarded-up factories and

struggling small towns, and saw opportunity to bolster a neglected supply chain and forgotten communities with dignified jobs, fair wages, and TK. I saw a world where we could lead by example, and influence an industry to reconsider the United States as a viable alternative to overseas production.

At the risk of sounding grandiose: I saw an opportunity to rebuild the fabric of our country through the decisions we made about the fabric and sewing of our products. Starting with a hoodie.

TEN YEARS AND A FEW THOUSAND CLASSIC FULL ZIPS LATER, NONE OF THAT HAS CHANGED.

We’ve built our business on the premise that great things happen when we put people first. And we’ll spend the next ten years reinvesting what we’ve earned right back into the communities who make it all possible by making our products with care and craftsmanship.

– Bayard Winthrop, CEO & Founder

FROM THE CAROLINAS

TO YOUR CLOSET.

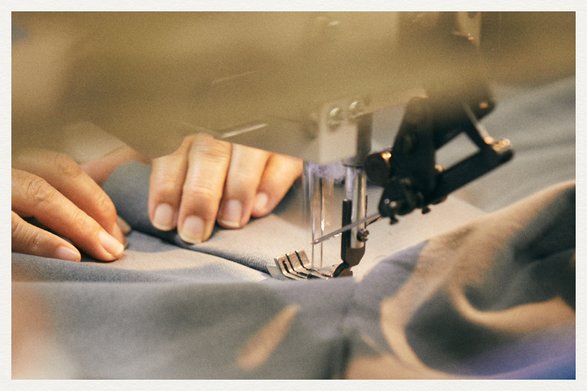

Back in 2012, Eagle—our factory in Middlesex, North Carolina—was on the brink of closure. We worked with the team to invest in new machinery, skill development, and operational capacity to support the production of a heavy-duty hoodie made of Carolina-grown cotton. Ten years later, we’re proud to support 95% of Eagle’s business—and 75 steady jobs.

FROM THE CAROLINAS

TO YOUR CLOSET

Back in 2012, Eagle—our factory in Middlesex, North Carolina—was on the brink of closure. We worked with the team to invest in new machinery, skill development, and operational capacity to support the production of a heavy-duty hoodie made of Carolina-grown cotton. Ten years later, we’re proud to support 95% of Eagle’s business—and 75 steady jobs.

THE WORSE YOU TREAT IT,

THE BETTER IT GETS.

We asked four self-made, independent workers and artists to tell us what sets their hoodies apart.

STRUCTURED SIDE PANELS

Kiki, The Racer

“ Movement is part of the job—you could say, it is my job. The structured side panels mean this hoodie moves with me and not against me on the road.”

REINFORCED ELBOWS

Apex, The Painter

“ Reinforced elbows are great extra padding, especially when I'm using my arms as a tripod.”

BODY SKIMMING FIT

Mariah, The Rancher

“ Is it too much to ask for a functional garment that also fits? I used to think so. Now, not so much.”

INCREDIBLE COMPACT COTTON

Matthew, The Farmer

“ I need a hoodie that allows for lots of flexibility while trying to maneuver around and under equipment. The fabric is soft, durable cotton but still very breathable”

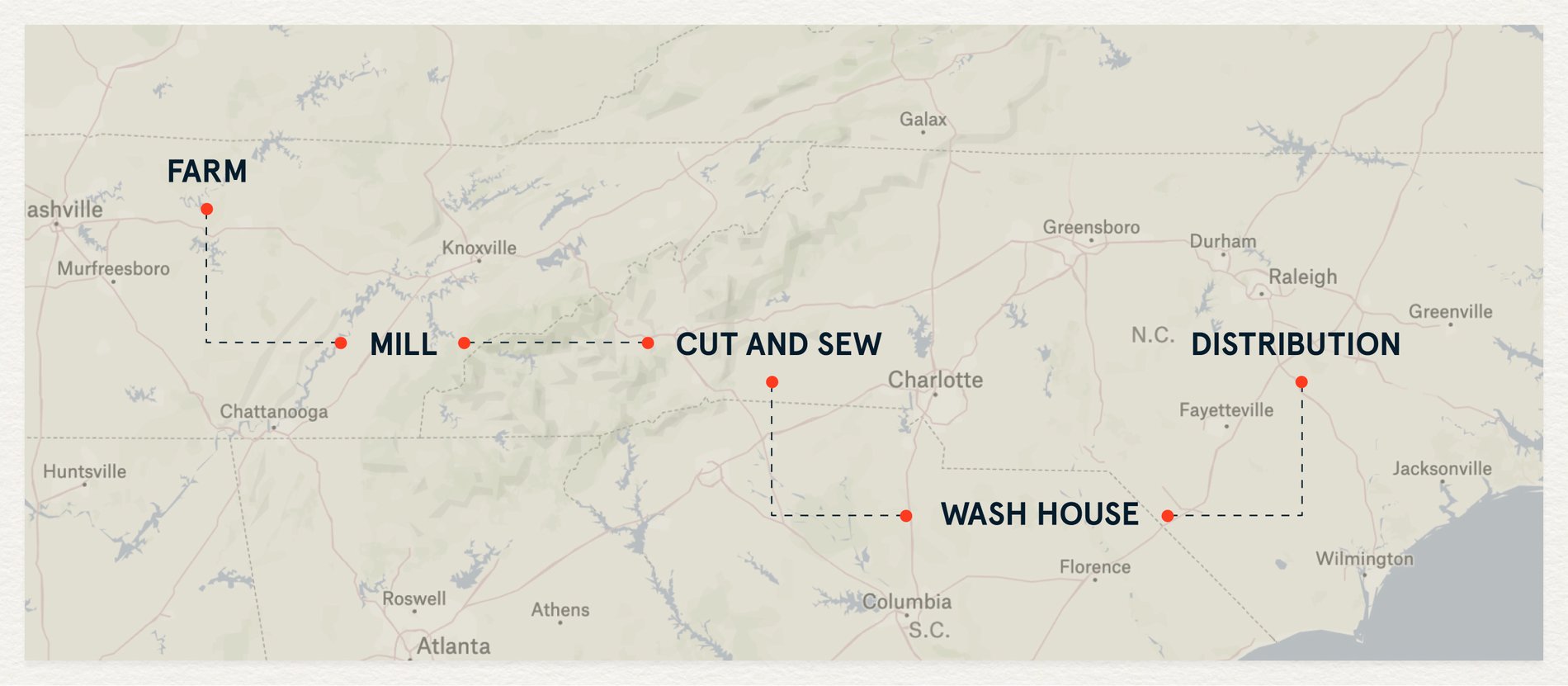

“THE 2,000 MILE HOODIE”

From the cotton field to our distribution center, our hoodie only travels 2,000 miles, which means less waste. We’ll break it down.

AMERICAN

MANUFACTURING

MATTERS.

AMERICAN MANUFACTURING MATTERS.